Agarbatti Making Machine Spare Parts

Table of Contents

Introduction

RP International is not just a domestic player; it has established a robust export network that spans across multiple countries. The company exports its products to markets in Asia, the Middle East, Europe, and North America. Its products have gained significant popularity in countries where the use of incense sticks is deeply ingrained in cultural and religious practices. We are the best agarbatti making machine supplier.

Incense sticks, or agarbatti, are used in many religious rituals, aromatherapy treatments, and even regular household fragrance. Using advanced agarbatti making machinery, automated manufacturing has replaced manual methods in the creation of these aromatic sticks. To guarantee smooth and effective functioning, these machines, like any other complicated machinery, need to have regular maintenance performed as well as have parts replaced sometimes. For manufacturers and anyone working in the agarbatti sector, this thorough handbook offers insightful information about the world of Agarbatti Making Machine replacement parts. It is essential to comprehend these components, their roles, and their significance in order to maximize output and reduce downtime.

Understanding the Agarbatti Making Machine

It’s crucial to comprehend the fundamentals of an agarbatti making machine before delving into spare parts. Usually, these devices automate a number of crucial procedures:

- Bamboo Stick Feeding: Bamboo sticks are automatically fed into the system by the machine.

- Application and Mixing of Powder: The bamboo sticks are coated with a mixture of wood powder, charcoal, and additional binding agents.

- Dipping and Rolling: To guarantee uniform dispersion, the coated sticks are dipped in a scent solution and then rolled.

- Drying and Packaging: Following drying, the completed agarbatti are packaged for delivery.

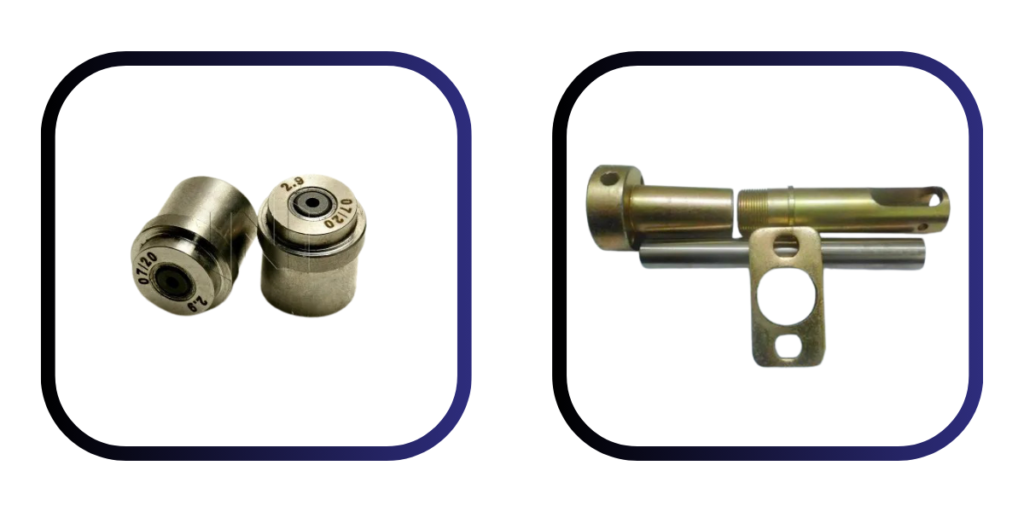

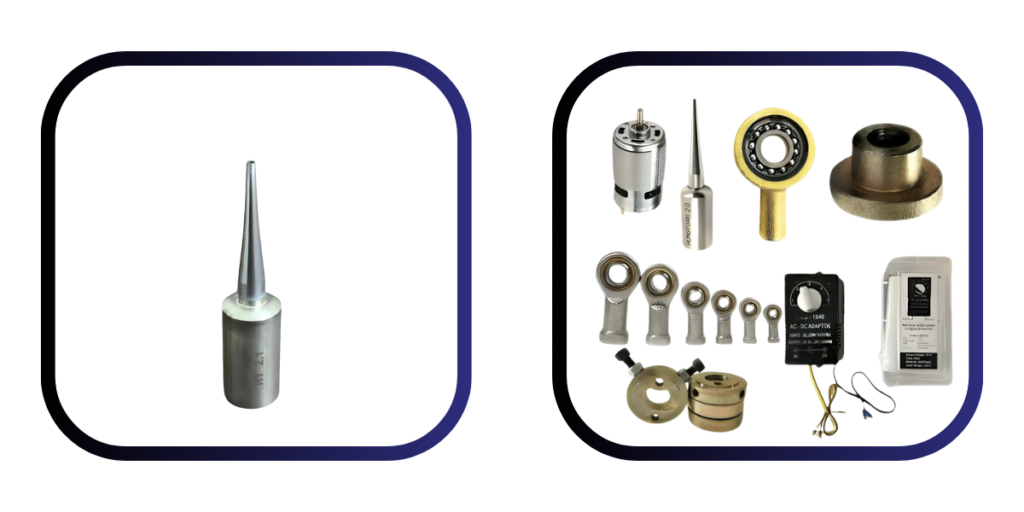

Key Spare Parts and Their Functions

An agarbatti making machine’s ability to operate smoothly hinges on each of its many parts operating as intended. Below is a summary of some essential replacement parts:

- Bamboo Stick Hopper/Feeder: This part is in charge of steadily keeping and supplying bamboo sticks to the machine. Jamming or irregular feeding are frequent problems that are frequently brought on by hopper or feeder mechanism wear and tear.

- Blades for powder mixers: These are essential for completely blending the raw ingredients into a uniform powder combination. Uneven mixing caused by worn blades can lower the agarbatti’s quality.

- Parts of the Coating/Application Unit: This unit coats the bamboo sticks with the powder mixture. Because they come into regular touch with the abrasive powder, parts including the brushes, applicator rollers, and coating drum are prone to wear and tear.

- Dipping Tank and Rollers: The fragrance solution is kept in the dipping tank, and the sticks are evenly coated thanks to the rollers. Problems may be caused by residue accumulation, damaged rollers, or tank leakage.

- Drying Chamber Components: To dry the agarbatti, the drying chamber circulates air or applies heat. Temperature sensors, fans, and heating elements are essential parts that require routine maintenance and repair.

- The agarbatti is moved through the various steps of the process via conveyor belts and chains. Slippage, misalignment, or fracture may result from wear and tear.

- These components lessen friction between moving parts: bushings and bearings. Increased friction, noise, and ultimately machine failure can result from wear and strain.

- Within the machine, power and motion are transmitted by gears and pulleys. Unpredictable machine functioning may result from damaged pulleys or gears.

- Pipes and nozzles: Used in liquid transfer procedures, such as applying scent. The process may be interrupted by leaks or obstructions.

- Electrical components consist of wire, control panels, sensors, and motors. When these parts malfunction, the machine may shut down entirely.

Importance of High-Quality Spare Parts

It is crucial to use high-quality spare parts for a number of reasons:

- Extended Machine Lifespan: Durable components require fewer replacements and increase the machine’s overall lifespan.

- Increased Productivity: Dependable components guarantee steady and seamless operation, reducing downtime and optimizing productivity.

- Improved Product Quality: The agarbatti’s constant quality in terms of scent, form, and burning characteristics is a result of properly operating components.

- Decreased Maintenance Costs: Although high-quality parts may cost more up front, they can save money over time by requiring fewer replacements and repairs.

- Safety: Making use of authentic and suitable parts guarantees the machine’s safe operation, safeguarding users and averting mishaps.

Why Choose RP International

At RP International, we are aware of how important premium replacement parts are to the production of agarbatti. We are a top supplier of a wide variety of replacement parts for agarbatti-making equipment of all kinds. We are a valued partner for agarbatti makers globally because of our dedication to quality, dependability, and client satisfaction.

- Broad Selection of Products: We have a large inventory of spare parts, so you can be sure to locate the parts you require for your particular equipment.

- Superior Products: We procure our components from reliable producers, ensuring their longevity and functionality.

- Competitive Pricing: We provide affordable costs without sacrificing quality.

- On-time Delivery: We aim to supply components in a timely and effective manner since we recognize how important it is to reduce downtime.

- Professional Support: Our staff of knowledgeable experts is on hand to offer technical support and direction.

Specifications of Agarbatti Making Machine Spare Parts

Choosing the appropriate Agarbatti Making Machine parts is made easier by being aware of spare part specifications. A comprehensive summary of specs for several spare components can be found below:

| Spare Part Name | Material | Size | Durability | Special Features |

| Nozzle | Stainless Steel | 5mm-10mm | High | Corrosion-resistant, precision cut |

| Piston | Alloy Steel | 10cm-15cm | High | High-strength, wear-resistant |

| Rollers | Rubber/Metal | 20cm-30cm | Medium | Smooth operation, long life |

| Motor | Copper Wiring | 1HP-5HP | High | Energy efficient, powerful torque |

| Belt | Rubber | Variable | Medium | Flexible, high tensile strength |

| Sensors | Electronic | Small | High | High sensitivity, precise detection |

| Gearbox | Cast Iron | Variable | High | Heavy-duty, smooth operation |

| Cutter Blade | High Carbon Steel | 5cm-10cm | High | Sharp cutting edge, rust-proof |

| Bearings | Steel | Standard | High | Low friction, high load capacity |

| Heating Element | Nickel Alloy | Variable | High | High-temperature resistance |

Benefits of Choosing RP International

- Decreased Downtime: Your production will continue to run thanks to our easily accessible spare parts.

- Better Machine Performance: We guarantee consistent agarbatti quality and optimal machine performance with our premium parts.

- Long-term cost savings are made possible by our affordable prices and sturdy parts.

- Professional Guidance: Our knowledgeable staff offers helpful technical assistance.

- Reliable Partnership: By offering dependable goods and services, we hope to establish enduring bonds with our clients.

Conclusion

Numerous cultural and business facets are significantly influenced by the agarbatti sector. Meeting the increasing demand for agarbatti products depends on the machines’ ability to operate effectively and dependably. To maximize output, reduce downtime, and guarantee the constant quality of agarbatti, it is crucial to comprehend the numerous replacement parts, their purposes, and the significance of employing high-quality components. Weare the best Agarbatti Making Machine Spare Parts Provider.

Manufacturers may obtain the assistance and spare parts they need to keep their equipment operating smoothly and efficiently by collaborating with a reputable supplier like RP International, which helps to ensure the agarbatti industry’s ongoing success. The essential components of a successful agarbatti production company are consistent upkeep, prompt replacement of worn parts, and an emphasis on quality.